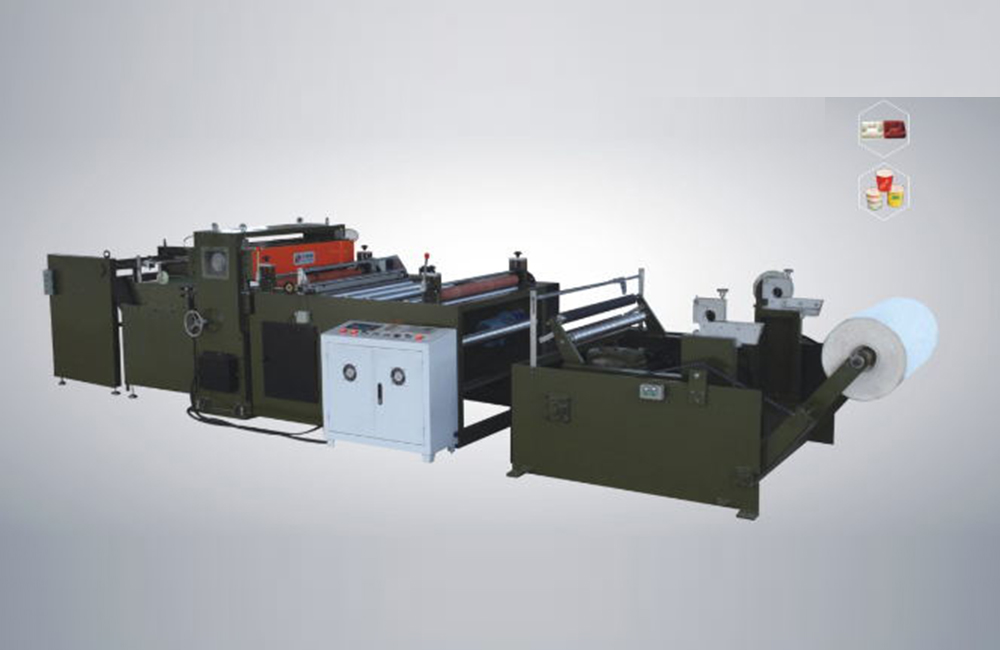

2.The rolled material feeding type is adopted for direct die cutting so as to save the edge trimming and carry out single-sheet cutting.Impression and die cutting can be directly carried out on the printed and coasted rolled materials so that the materials are processed into the final products at a time.

3.The machine has such advantages as high automation degree and high production efficiency etc.

4.The machine is equipped with high-precision computerized photoelectric automatic tracking inspection,servo motor automatic positioning system,mechanical automatic feeding device and automatic feeding deviation correcting device.Its main performance features are as follows:convenient length setting,high positioning precision,stable feeding,even tension and stepless speed adjustment.

5.Product of special specifications can be customized.

|

Model |

HSG680 |

HSG1000 |

|

Maximum area of die cutting and mark impression(mm)(Random arrangement is available within this area) |

680*640 |

1000*620 |

|

Applicable range |

80-500/m2(Material science) |

800-500/m2(Material science) |

|

Die cutting precision |

+_0.15mm |

+_0.15mm |

|

Die cutting speed |

4200(times/hour) |

4200(times/hour) |

|

Maximum unwinding diameter |

1100mm |

1500mm |

|

Maximum die cutting pressure |

120KN |

180KN |

|

Total power |

18KW |

25KW |

|

Main machine power |

11KW |

15KW |

|

Outline dimensions of machine(mm) |

5800*1800*1600 |

7000*2000*1800 |

|

Machine weight |

5500kg |

7500kg |