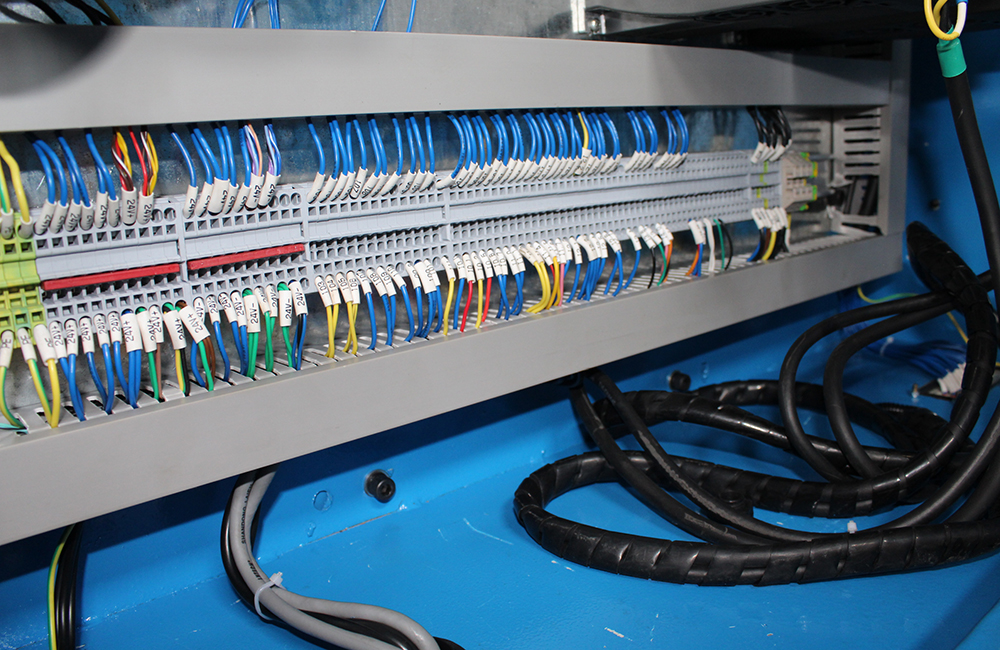

The machine is controlled by PLC and has a human-machine interface to ensure that some parameters such as feeding length, transverse moving distance, rising height etc. are easily set through the touch screen.

Single, double or multiple cutting dies may be fitted on the punch of the machine to perform the die-cutting of materials by precisely controlling machine movement along the directions of X and Y.

With memory function, the machine may store various operating modes. Installing a suitable cutting die makes it possible for the machine to implement manufacturing process in the preset operating mode.

The machine is driven by a servo motor to ensure accurate feeding. The use of servo motor and ball screw as drive systems enables the punch to achieve precise positioning.

The machine supports manual and automatic modes in which operators only need to pick up the finished products. This may help greatly improve working efficiency and reduce labor intensity.

The machine is enclosed by protective mesh to enhance the safety of the machine.

Some special specifications may be customized.

Optional:

·Cutting sheet micro-inching device

·Winding and storage stand

·Pneumatic cutting die clamping device

·Safety light curtain

|

Model |

HSYT-250ET |

HSYT-350B1 |

HSYT-500B1 |

HSYT-800 |

|

Maximum cutting force/KN |

250 |

350 |

500 |

800 |

|

Breadth of applicable materials/MM |

≤1600 |

≤1600 |

≤1600 |

≤1600 |

|

Size of the punch/MM |

500*500 |

500*500 |

500*500 |

500*500 |

|

Adjustable stroke/MM |

5-150 |

5-150 |

5-150 |

5-150 |

|

Total power |

7 |

8 |

9 |

12.5 |

|

Dimensions of the machine/MM |

2700*2900*2600 |

2700*2900*2700 |

2700*2800*2700 |

2700*2760*2680 |

|

Weight/KG |

3000 |

3800 |

4500 |

6000 |